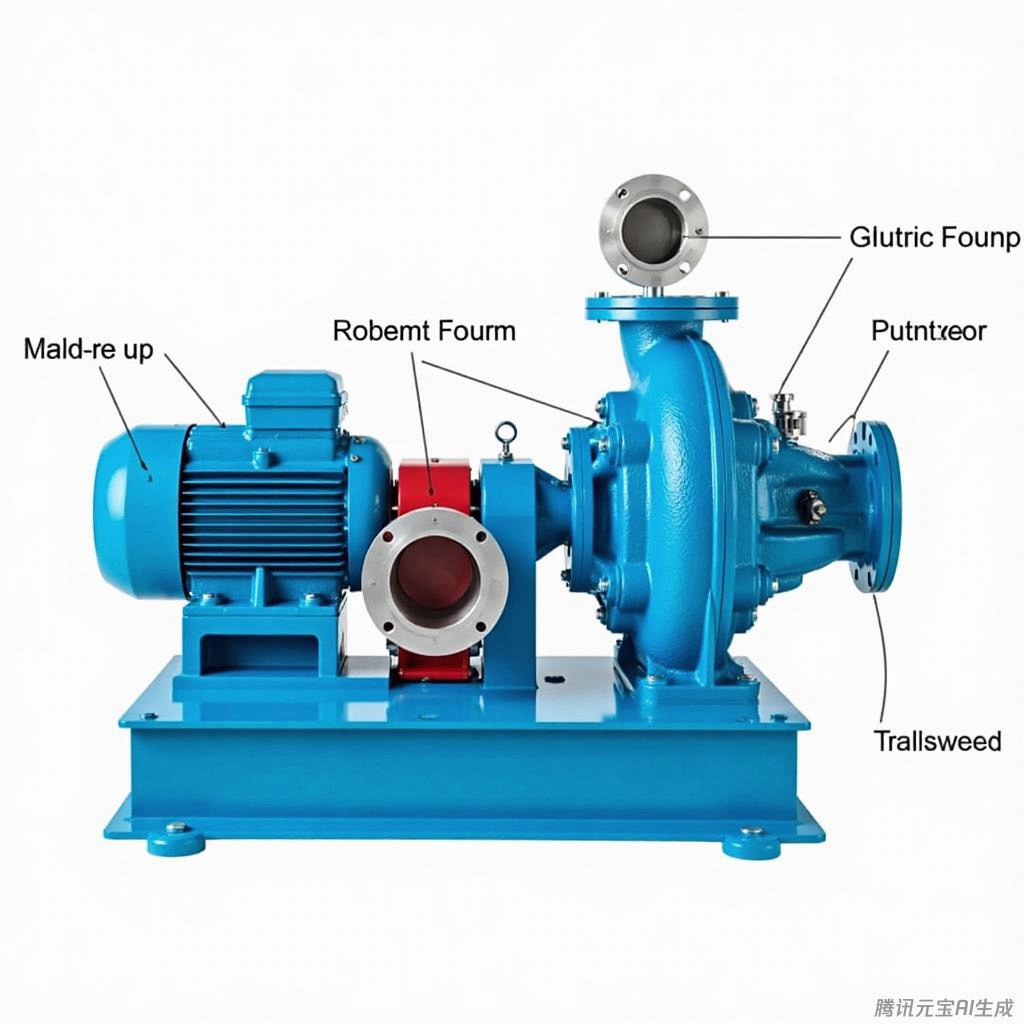

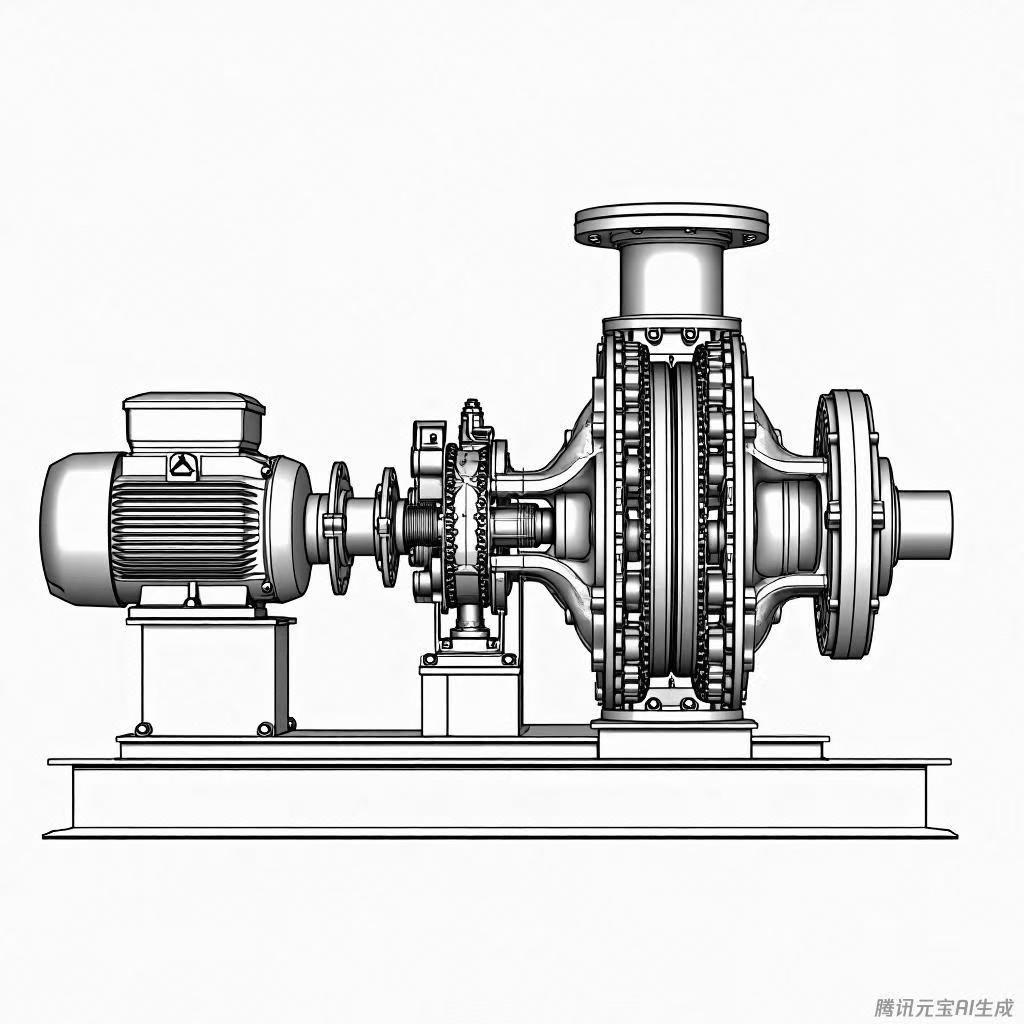

Semiconductor Manufacturing In semiconductor manufacturing, even extremely minute amounts of metal ions, particulate impurities, or organic contaminants can lead to catastrophic consequences. These impurities may alter the electron transport paths inside the chip, increase resistance, cause severe heating of the chip, and degrade its performance. Impurities may also trigger issues such as short circuits, preventing the chip from functioning properly. Relevant studies have shown that during the chip manufacturing process, the loss of yield due to the purity of chemical reagents can reach 20%- 30%. This is undoubtedly a huge challenge for the semiconductor industry, which pursues high precision and high yield. The Key Role of Magnetic Pumps Throughout the entire semiconductor manufacturing process, magnetic pumps ensure the continuity of chemical reagent delivery. They work continuously and stably, enabling the timely supply of chemical reagents required for different stages and avoiding production stoppages caused by interruptions in reagent supply. Take the thin film deposition stage as an example. Specific gases and liquid chemical reagents need to be continuously supplied to the reaction chamber. The stable operation of the chemical pump ensures the continuity of the deposition process, allowing the film to grow uniformly and guaranteeing the electrical performance and reliability of the chip. As a highly favored type of chemical pump in the semiconductor industry, the most notable feature of magnetic pumps is their unique design without mechanical seals. They use magnetic couplings to transmit power. The pump shaft and motor shaft interact through magnetic force, eliminating the need for traditional mechanical seal devices. This fully sealed design is like putting on a solid "protective armor" for the chemical reagents, fundamentally eliminating the possibility of medium leakage. In the semiconductor manufacturing process, even the tiniest leakage can cause serious pollution problems, and the emergence of magnetic pumps perfectly solves this hidden danger. During the delivery of photoresist, magnetic pumps can ensure the stable flow of photoresist within closed pipes without any leakage, thus guaranteeing the high purity of the photoresist. In the delivery of high-purity electronic grade hydrofluoric acid, the fully sealed characteristic of magnetic pumps effectively prevents the contact between hydrofluoric acid and the external air, preventing the volatilization of hydrofluoric acid due to leakage and the resulting harm to the environment and personnel. At the same time, it also ensures that the purity of hydrofluoric acid is not affected, providing a reliable guarantee for the subsequent etching process. Selection Points 1.When selecting a chemical pump for delivering high-purity chemical reagents in the semiconductor industry, many key factors need to be carefully considered. Flow rate is one of the primary factors. Th...

Read More English

English français

français русский

русский español

español português

português العربية

العربية ไทย

ไทย Tiếng Việt

Tiếng Việt Indonesia

Indonesia  中文

中文

IPv6 network supported

IPv6 network supported