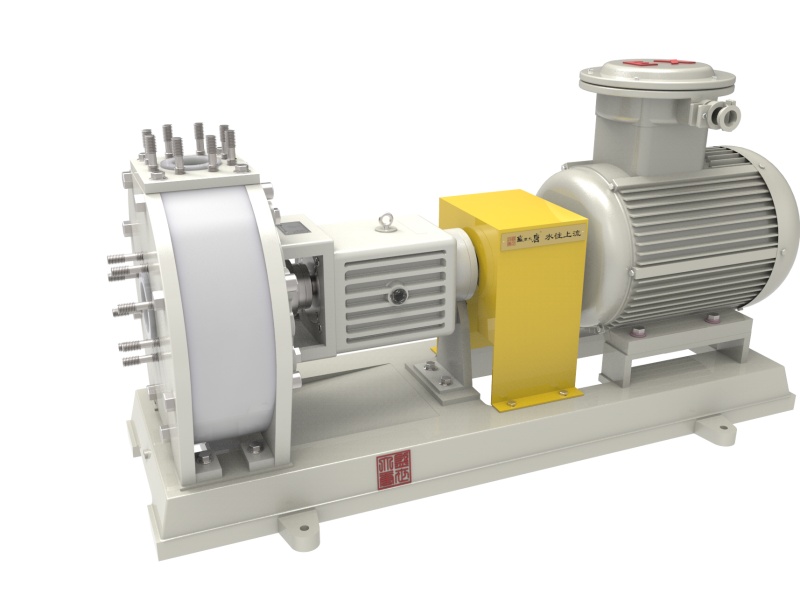

Full plastic anti-corrosion abrasion resistance electric centrifugal pump —— it uses high - quality plastics for parts like the impeller and shell. This pump has excellent wear resistance, able to handle media with solid particles. It shows great corrosion - resistance to various chemicals. With a well - designed impeller, it operates efficiently with low noise and vibration, suitable for multiple industries.

MOQ:

1Package:

CustomizedColor:

CustomizedMaterial:

Engneering plasticWorking Temp:

UHMWPE ≤ 100 ℃; Fluoroplastics ≤ 150 ℃.Working Pressure:

1.6 Mpa

Product overview

The THNP (horizontal centrifugal pump) full-plastic anti-corrosion and abrasion-resistant electric centrifugal pump is a newly electric centrifugal pump meticulously crafted by our company specifically for the nonferrous smelting sector. This pump is fabricated from ultra-high molecular weight polyethylene engineering plastic. It not only exhibits outstanding corrosion resistance but also demonstrates very good wear resistance and exceptional impact resistance. With its broad application scope, it is particularly well-suited for corrosive media containing a high solid content.

Product advantages

1. It is a high pressure centrifugal pump 3 phase motor driven that has been designed and manufactured with reference to the JB/T8688 - 2013 standard and in combination with the process of non-metallic pumps. It features corrosion resistance, wear resistance, high mechanical strength, high efficiency, and energy saving.

2. The inner pressure bearing metal support framework is embedded within the pump shell and pump cover. This overcomes the drawbacks of unstable mechanical properties resulting from compression deformation and cold shrinkage deformation of the entire plastic pump body.

3. The seal of the pump has been enhanced. Through the improvement of the power seal structure, the service life of the seal is extended compared to that of the conventional power seal. It can be utilized under the same working conditions. The API682 standard seal arrangement and flushing scheme can be adopted.

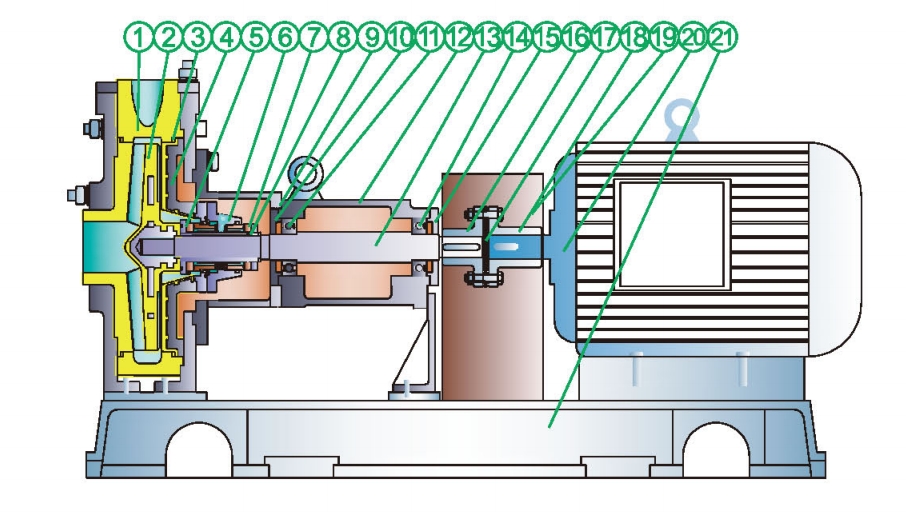

Material list

| Part | Material | Part | Material | Part | Material |

| ①Pump casing | Engineering plastic | ⑧Dynamic ring | SIC/hard alloy | ⑮Gland of back bearing | HT200 |

| ②Impeller | Engineering plastic | ⑨Bracket | HT200 | ⑯Pump coupling | 45# |

| ③Gasket | PTFE/Fluororubber | ⑩Gland of front bearing | HT200 | ⑰Diaphragm | 304 |

| ④Pump cover | HT200/Engineering plastic | ⑪Front bearing | rolling bearing | ⑱Electric coupling | 45# |

| ⑤Static ring | SIC/hard alloy | ⑫Bearing box | HT200 | ⑲Shield | 304 |

| ⑥Shaft sleeve | SIC | ⑬Pump shaft | 2Cr13/3Cr13 | ⑳Electric motor | Customized |

| ⑦Seal gland | 304/316/316L | ⑭Rear bearing | rolling bearing | ㉑Base plate | HT200 |

Structural diagram

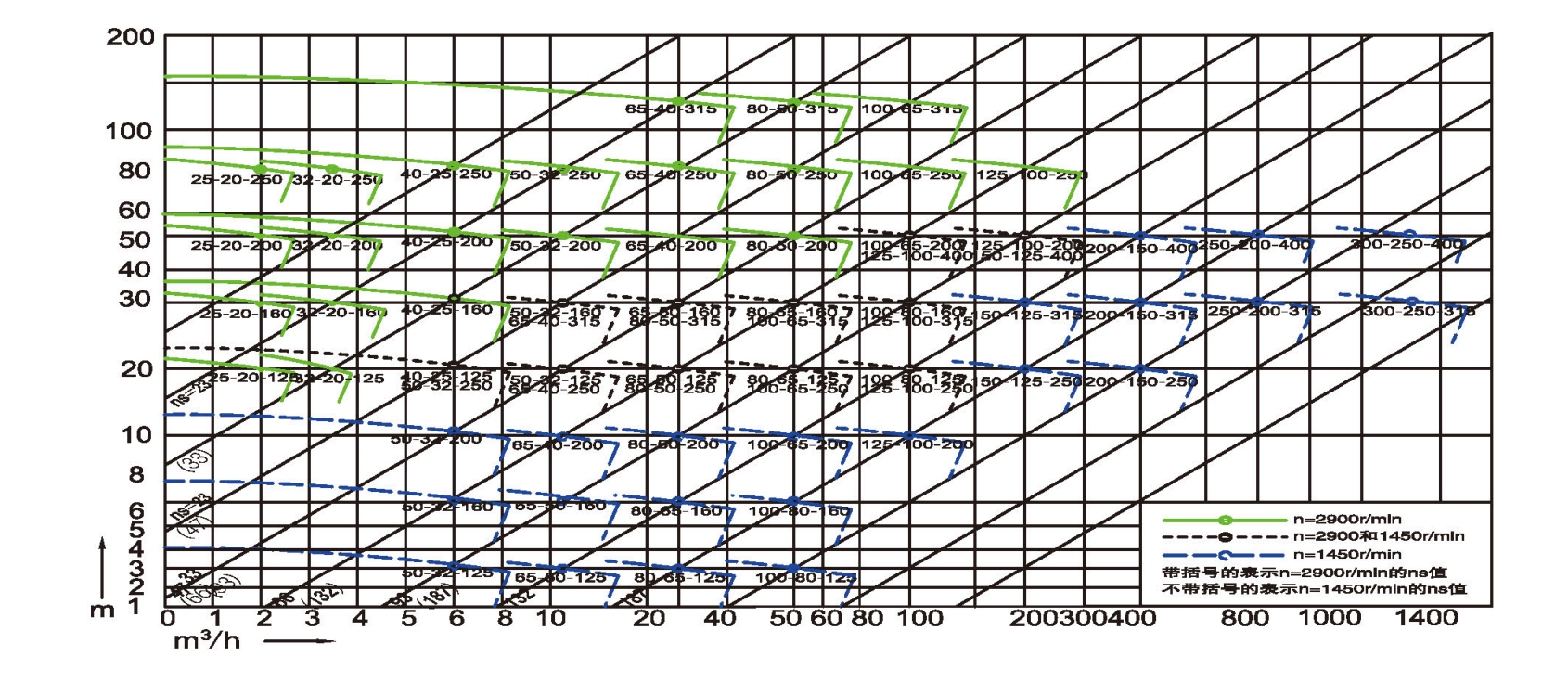

Performance range

Design pressure: 1.6Mpa; Diameter: 25 ~300mm; Flow: 0.75~1550m³/h; Head: 4.6~125m Power: 0.75 ~ 280KW

Applicable temperature: ①UHMWPE ≤ 100 ℃;

②Fluoroplastics ≤ 150 ℃.

Product application

It is especially suitable for the transportation of various acids (such as phosphoric acid pump), corrosive pulp, electrolyte, sewage and other media in the hydrometallurgy of lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and so on.

Others