The TCSF no-leakage lining fluorine magnetic pump is a remarkable device. It is lined with fluorine, which endows it with excellent corrosion resistance. The magnetic drive mechanism guarantees a leak-free operation, making it an ideal choice for the transfer of fluids in chemical and industrial applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

FluoroplasticWorking Temp:

-20 to 120 ℃,Any concentration of acid-base mediumWorking Pressure:

1.6 MPa

Product overview

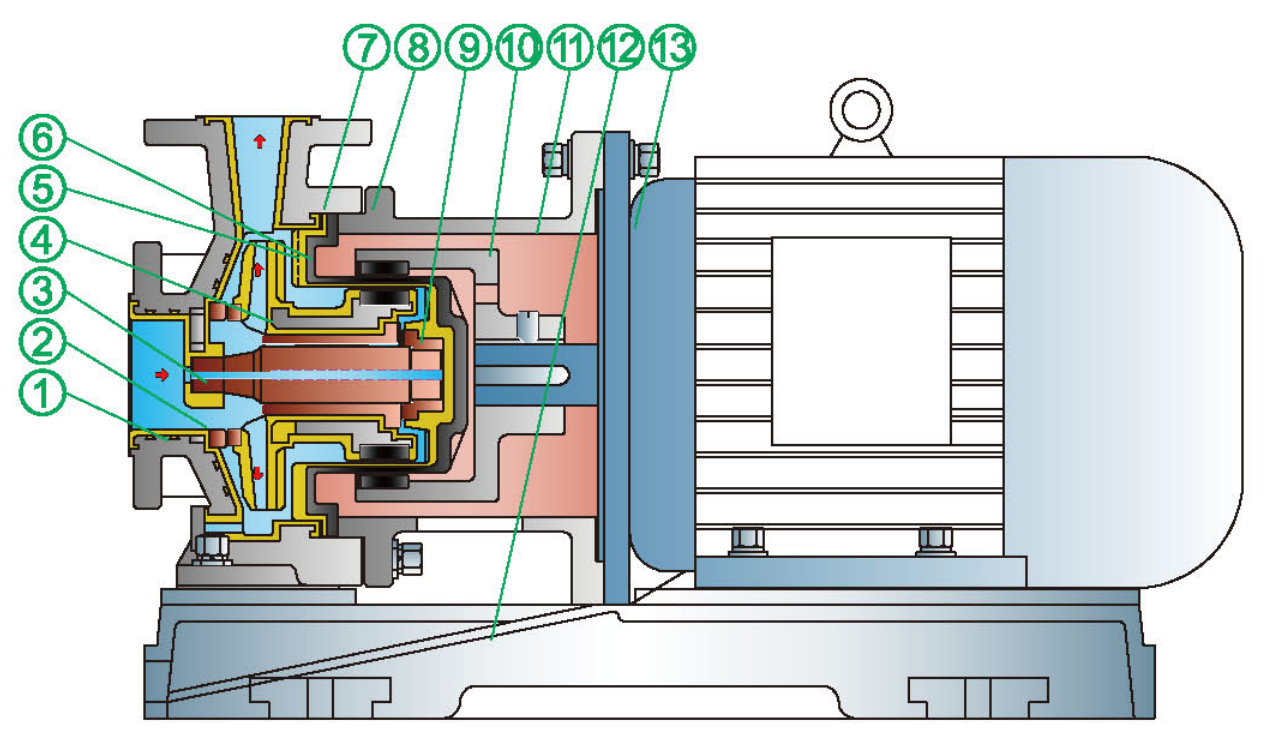

The TCSF series fixed shaft magnetic pump (centrifugal magnetic pump) represents an improvement and optimization upon the traditional magnetic pump. In the conventional magnetic pump structure, the magnetic rotor drives the impeller to rotate via the pump shaft. However, in the TCSF series fixed shaft magnetic pump, the structure has been modified such that the magnetic rotor directly drives the impeller to rotate. Here, the shaft remains fixed and does not rotate; instead, it serves solely as a support.

Product advantages

1. The transmission efficiency and stability of the pump have been enhanced, while the number of internal parts has been reduced.

2. The pump has a higher degree of generalization. The magnetic transmission part of the pump is configured based on the power.

3. The design of the magnetic circuit has been optimized, resulting in a lower manufacturing cost and a smaller floor area for the pump.

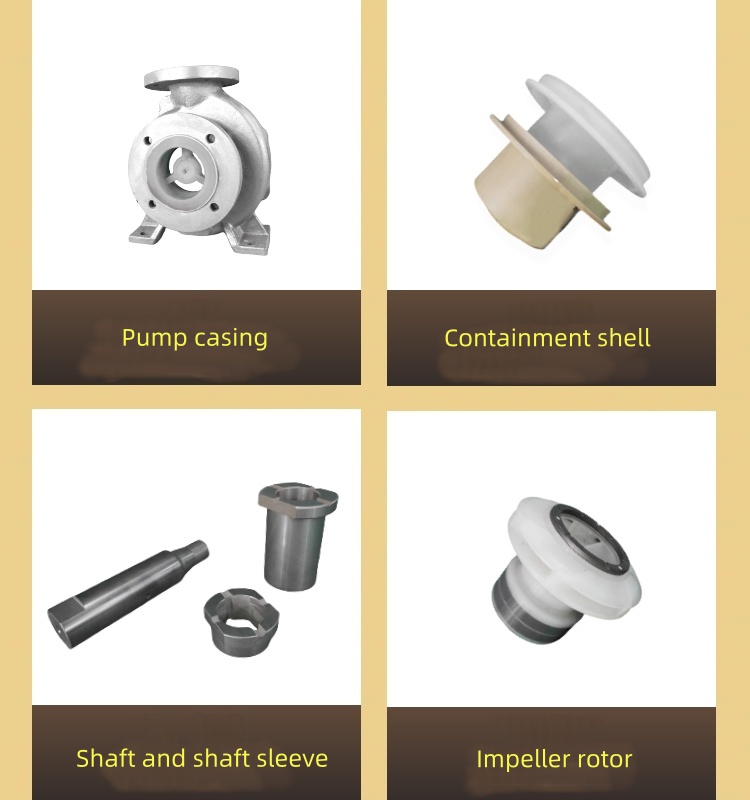

Material List

| Part | Material | Part | Material | Part | Material |

| ① Pump body | HT200/F46/PFA | ⑥ Reinforcing sleeve | PEEK | ⑪ Bracket | HT200/ZG |

| ② Pump body mouth ring | Filled PTFE/Silicon carbide | ⑦ Seal ring | Fluororubber/Teflon | ⑫ Base | HT200/Channel steel |

| ③ Pump shaft | Silicon carbide/Pressureless | ⑧ Axle sleeve | SIC/Pressureless | ⑬ Motor | Per client request |

| ④ Impeller assembly | 45# F46/PFA/Permanent magnet | ⑨ Spacer bearing | SIC/Pressureless | ||

| ⑤ Isolation sleeve | F46/PTFE | ⑩ Outer rotor assembly | HT250/Permanent magnet |

Structural diagram

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 32-20-115F | 3.2 | 380V | F4/F46/F50 | 32*20 | ||

| 40-25-120F | 6.3 | 380V | F4/F46/F50 | 40*25 | ||

| 40-40-120F | 6.3 | 380V | F4/F46/F50 | 40*40 | ||

| 50-32-120F | 12.5 | 380V | F4/F46/F50 | 50*32 | ||

| 25-20-125 | 1.1 | 2.5 | 20 | 380V | F4/F46/F50 | 25*20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | F4/F46/F50 | 25*20 |

| 25-20-200 | 4 | 2.5 | 50 | 380V | F4/F46/F50 | 25*20 |

| 25-20-250 | 7.5 | 2.5 | 80 | 380V | F4/F46/F50 | 25*20 |

| 32-20-125 | 1.1 | 3.2 | 20 | 380V | F4/F46/F50 | 32*20 |

| 32-20-160 | 3 | 3.2 | 32 | 380V | F4/F46/F50 | 32*20 |

| 32-20-200 | 4 | 3.2 | 50 | 380V | F4/F46/F50 | 32*20 |

| 32-20-250 | 7.5 | 3.2 | 80 | 380V | F4/F46/F50 | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | F4/F46/F50 | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | F4/F46/F50 | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | F4/F46/F50 | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | F4/F46/F50 | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | F4/F46/F50 | 40*25 | |

| 50-32-125 | 3 | 12.5 | 20 | 380V | F4/F46/F50 | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | F4/F46/F50 | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | F4/F46/F50 | 50*32 |

| 50-32-250 | 11 | 12.5 | 80 | 380V | F4/F46/F50 | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | F4/F46/F50 | 50*32 | |

| 65-50-125 | 4 | 25 | 20 | 380V | F4/F46/F50 | 65*50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | F4/F46/F50 | 65*50 |

| 65-40-200 | 11 | 25 | 50 | 380V | F4/F46/F50 | 65*40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | F4/F46/F50 | 65*40 |

| 65-40-315 | 37 | 25 | 125 | 380V | F4/F46/F50 | 65*40 |

| 80-65-125 | 7.5 | 50 | 20 | 380V | F4/F46/F50 | 80*65 |

| 80-65-160 | 11 | 50 | 32 | 380V | F4/F46/F50 | 80*65 |

| 80-50-200 | 15 | 50 | 50 | 380V | F4/F46/F50 | 80*50 |

| 80-50-250 | 30 | 50 | 80 | 380V | F4/F46/F50 | 80*50 |

| 80-50-315 | 45 | 50 | 125 | 380V | F4/F46/F50 | 80*50 |

| 100-80-125 | 11 | 100 | 20 | 380V | F4/F46/F50 | 100*80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | F4/F46/F50 | 100*80 |

| 100-65-200 | 30 | 100 | 50 | 380V | F4/F46/F50 | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | F4/F46/F50 | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | F4/F46/F50 | 100*65 |

| 125-80-160 | 30 | 160 | 32 | 380V | F4/F46/F50 | 125*80 |

| 125-100-200 | 55 | 200 | 50 | 380V | F4/F46/F50 | 125*100 |

| 125-100-250 | 75 | 200 | 80 | 380V | F4/F46/F50 | 125*100 |

| 125-100-315 | 22 | 100 | 125 | 380V | F4/F46/F50 | 125*100 |

| 125-100-400 | 37 | 100 | 50 | 380V | F4/F46/F50 | 125*100 |

| 150-125-250 | 22 | 200 | 20 | 380V | F4/F46/F50 | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | F4/F46/F50 | 150*125 |

| 150-125-400 | 55 | 200 | 50 | 380V | F4/F46/F50 | 150*125 |

| 200-150-250 | 55 | 400 | 20 | 380V | F4/F46/F50 | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | F4/F46/F50 | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | F4/F46/F50 | 200*150 |

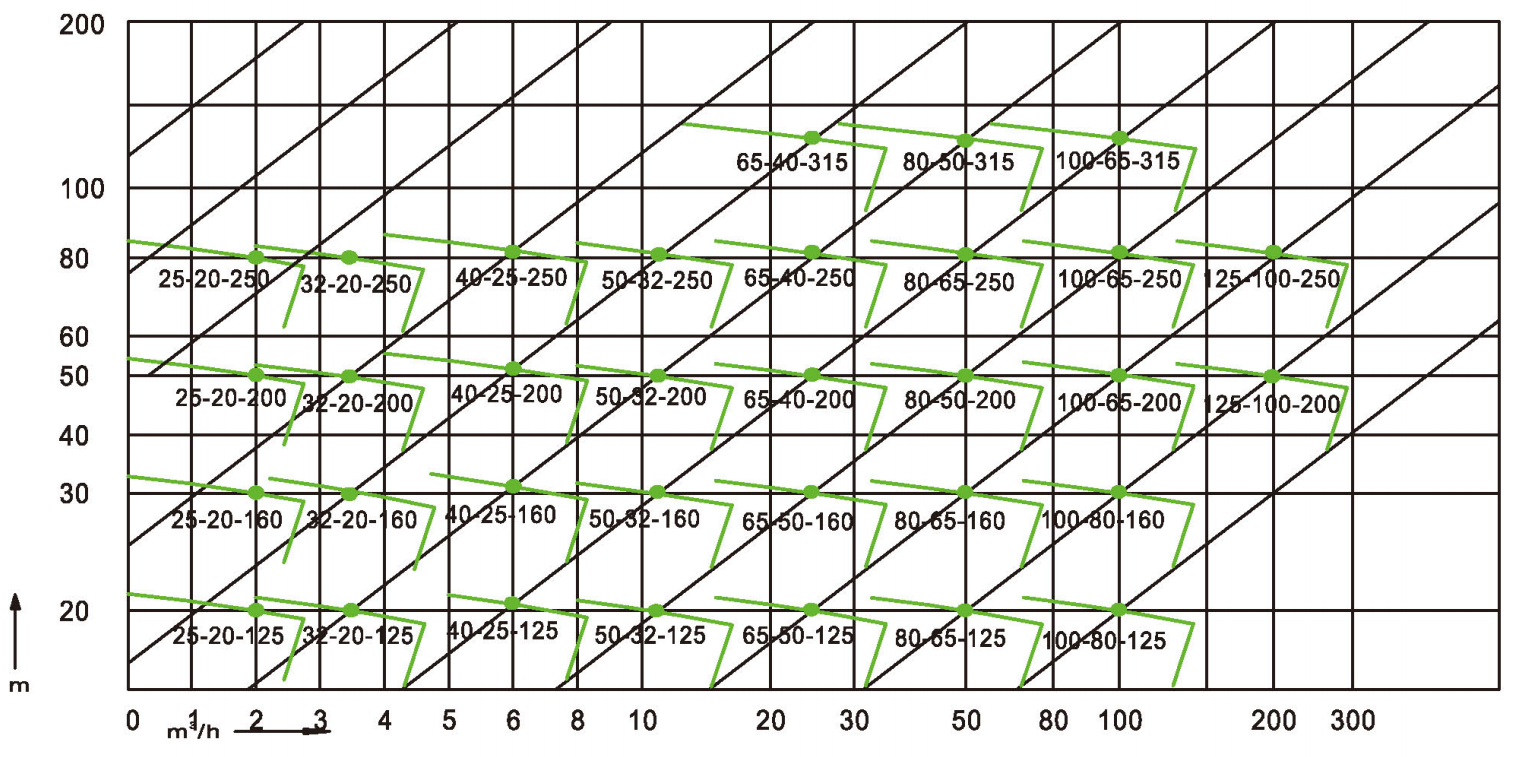

Performance range

Design pressure: 1.6 MPa, Flow: 0.75~460 m³/ h , Lift: 5~125 m, Power: 0.55~110 KW.

Applicable temperature :-20~120 ℃ , acid - base medium of any concentration.

Product application

It finds extensive application in various industries such as benzene pump in petroleum, chemical engineering, acid handling pump, alkali handling pump, smelting, rare earth processing, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, electrolysis, pickling, and so on.

Others