The TCAF Series chemical process no-leakage magnetic pump utilizes a magnetic coupling for sealing, thereby achieving zero leakage. It is an ideal choice for chemical processes, as it ensures both safety and the stable transfer of fluids.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-30 to 180 ℃Working Pressure:

2.5 MPa

Product review

The TCAF series(chemical resistant pump)leak-free magnetic drive centrifugal chemical process pump(industrial chemical pump)is designed and developed in line with the Api685-2000 standard. All the parts that come into contact with the fluid (flow passage parts) are fabricated from fluoroplastics, enabling it to transport corrosive media such as acids, alkalis, and oxidants, regardless of their concentration (strength). The isolation sleeve is crafted from special materials, which possess high-strength mechanical properties and effectively eliminate the occurrence of magnetic eddy current within the magnetic pump.

Product advantages

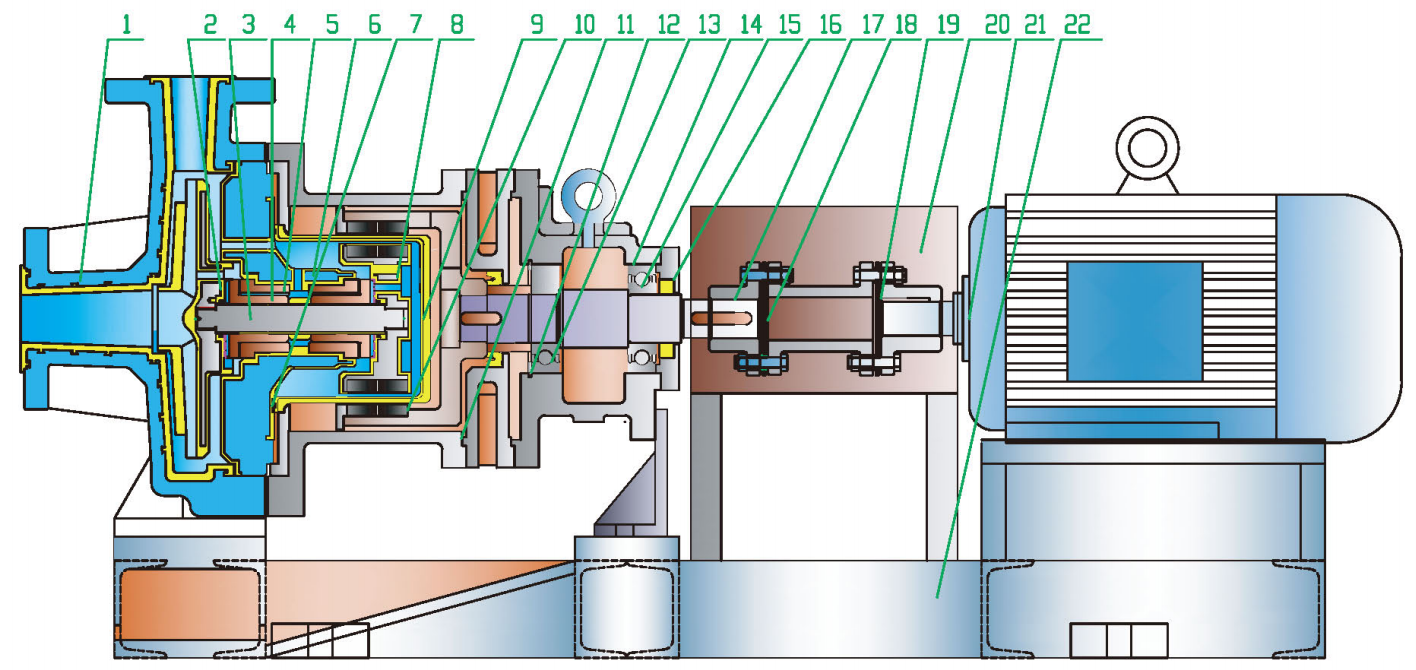

Material List

| Part | Material | Part | Material | Part | Material |

| ① Pump body | ZG line F50/PFA | ⑨ Support | Permanent magnetic/45# line F50 | ⑰ Pump coupling | 45# |

| ② Impeller | 45# lineF50 | ⑩ Outer magnet | Permanent magnetic/ZG | ⑱ Diaphragm | 304 |

| ③ Pump shaft | SIC/SSIC | ⑪ Connecting frame | ZG | ⑲ Electric coupling | 45# |

| ④ Shaft sleeve | SIC/SSIC/45 line F50 | ⑫ Front gland of bearing | ZG/A3 | ⑳ Shield | Open type spark free |

| ⑤ Thrust coter | SIC/SSIC | ⑬ Front bearing | Gcr15 | ㉑ Motor | Per client request |

| ⑥ Pump cover | ZG/F50/PFA | ⑭ Bearing box | ZG | ㉒ Floor | ZG/A3 |

| ⑦ Gasket | F4/FKM | ⑮ Back bearing | Gcr15 | ||

| ⑧ Inner magnet | Permanent magnetic/45#steel/F50 | ⑯ Back gland of bearing | ZG/A3 |

Structural diagram

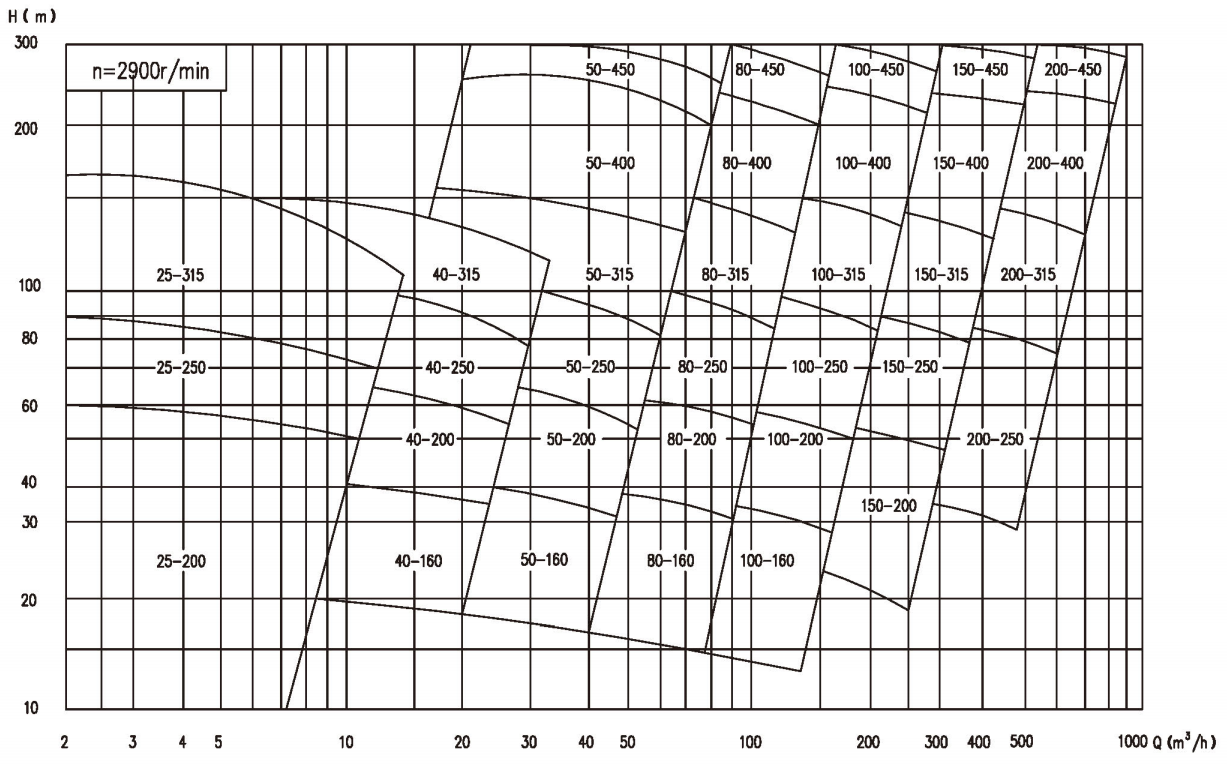

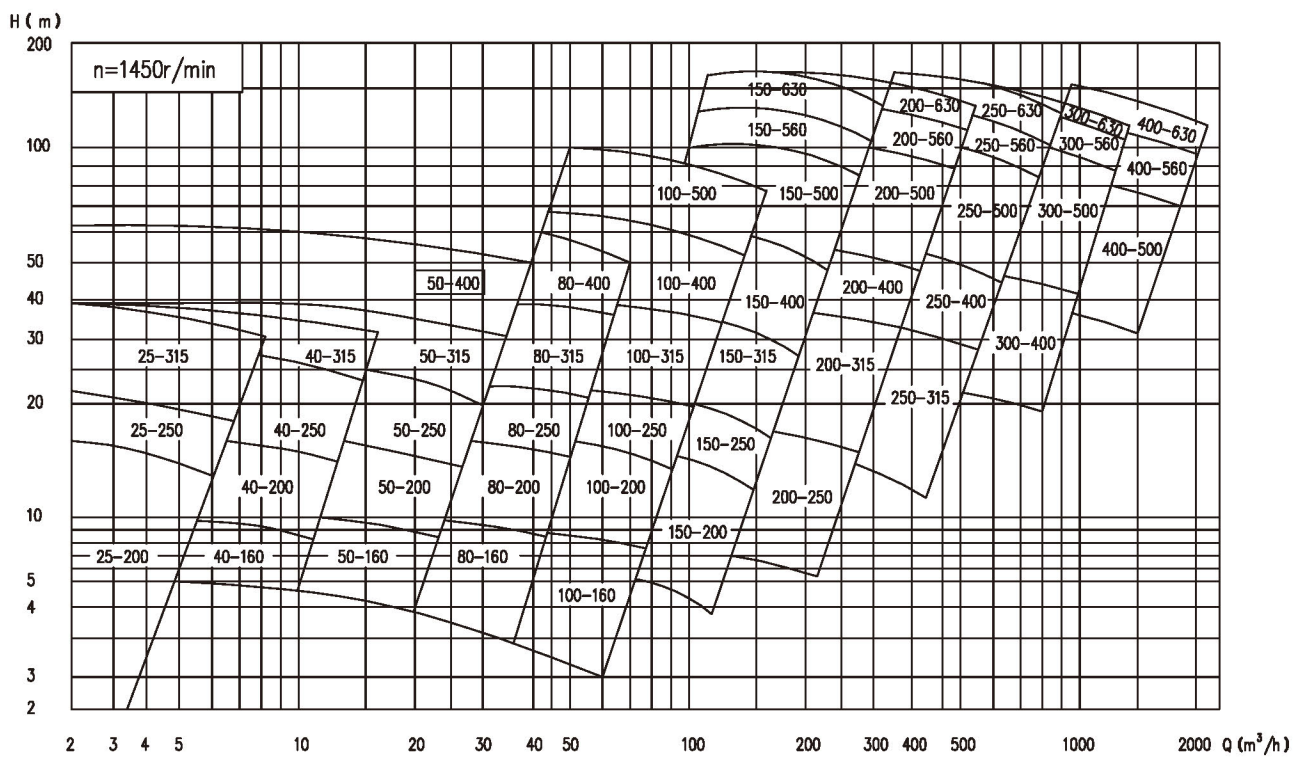

Performance range

Design pressure :2.5MPa, Flow :5.5~1900m³/h, Lift :16~200m, Power :2.2~315kw.

Applicable temperature :-30~180℃.

Product application ---Electric chemical transfer pumps, ammonia pump, corrosive chemical pumps, acid pumps, chlorine pump, acid transfer pump, methanol pump, liquid chlorine pump, ammonia transfer pump,

It finds extensive application in the transportation processes within the production of various fields such as chemical, petrochemical, pharmaceutical, and printing and dyeing industries. It is specifically used for transporting clean liquids with a specific gravity not exceeding 1.84. This equipment is chemical transfer pump, which is particularly well-suited for handling the transportation of liquid media that are flammable, explosive, toxic, harmful, corrosive, or precious. It has the capability to transport inorganic and organic acid solutions, including sulfuric acid, nitric acid, hydrochloric acid, and phosphoric acid, across a wide range of temperatures and concentrations.