The TCA/E no-leakage petrochemical magnetic pump is specifically engineered for application in the petrochemical industry. Its most notable feature is the absence of leakage, which significantly enhances operational safety. By virtue of being constructed with high-quality materials and incorporating advanced technological elements, this pump offers a high degree of reliability.

In addition to its functional advantages, the pump has a compact design. This characteristic makes it not only easy to install but also convenient for maintenance. As a result, it can efficiently facilitate the transfer of fluids even within the demanding and harsh conditions prevalent in the petrochemical environment.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-60 to 300 ℃,New material withstands temperatures up to 450°CWorking Pressure:

2.5 to 5.0 Mpa

Product overview

The TCA series leak-free magnetic drive centrifugal chemical process pump(chemical resistant pump)is a world-leading high-tech product. It is developed by introducing German technology and is in line with the API 685 - 2000 standard for sealless centrifugal pumps, specifically designed for application in the petroleum, heavy chemical, and natural gas industries.

Product advantages

1. The materials used for the pump include 304, 316, 904L, duplex steel, titanium alloy, Hastelloy, and so on.

2. The manufacturing standard adheres to the Api685-2000 standard for production, with options such as TCA foot support and TCE center support.

3. The magnet is a novel type of permanent magnet that exhibits excellent magnetic properties, high temperature resistance, and no demagnetization.

4. The shaft sleeve and sliding bearing are made of high wear-resistant silicon carbide (SSIC) and are equipped with lubrication grooves, which effectively ensure the service life of the pump.

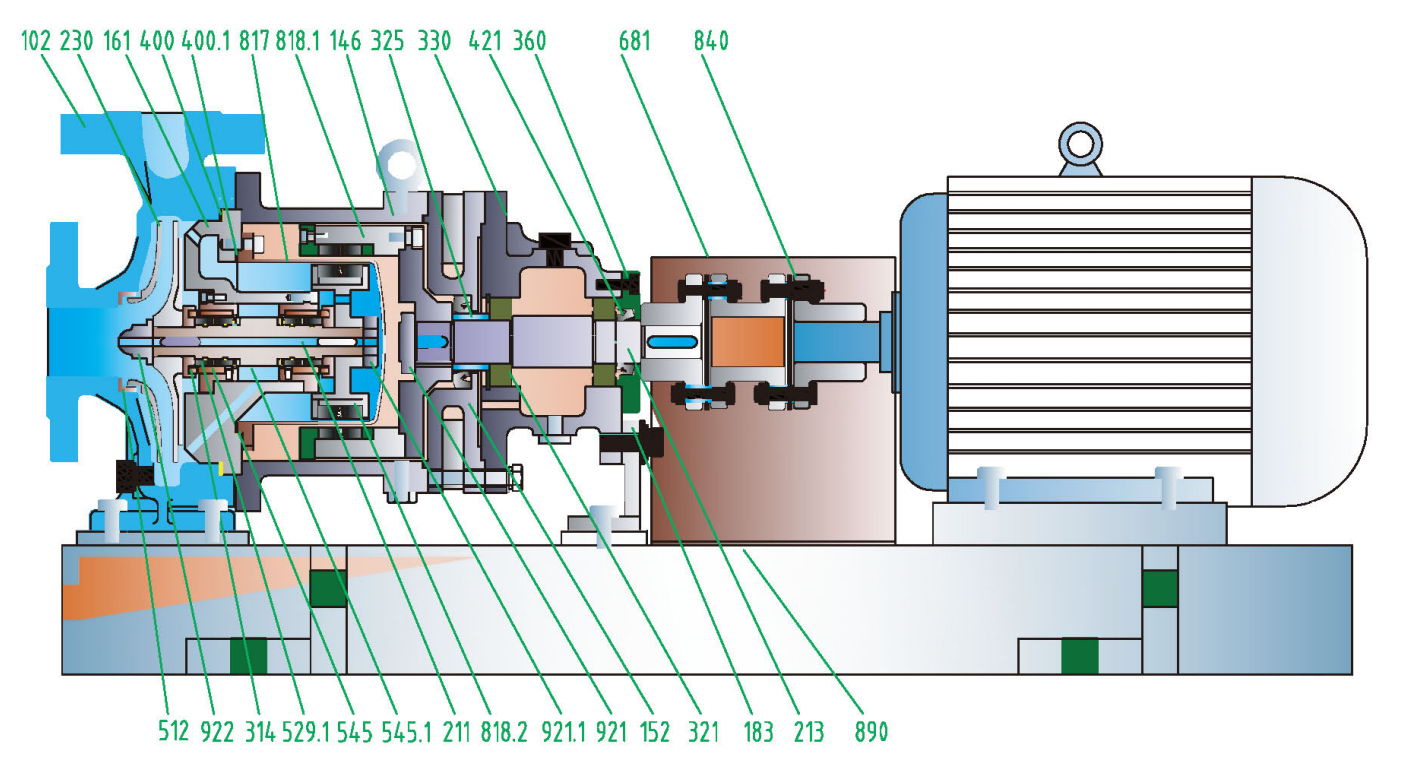

Material List

| Part | Material | Part | Material | Part | Material |

| 102 Pump body | 304/316/316L | 545.1 Bearing bushing | 304/316/316L | 545 Slide bearing | SSic/hard alloy |

| 230 Impeller | 304/316/316L | 890 Base plate | HT200/45 | 529.1 Bearing sleeve | SSic/hard alloy |

| 161 Pump cover | 304/316/316L | 213 Driven plate | 2Cr13 | 314 Thrust collar | SSic/hard alloy |

| 817 Distance sleeve | 316L/TA2/HC276 | 183 Bracket plate | HT 200 | 922 Impeller nut | 304/316/316L |

| 818.1 Outer magnet component | Permenant magnet/ZG | 152 Cooling bracket | 45 | 512 Wearing ring | 304/316/316L |

| 146 Bracket | HT 200 | 921 Locknut | 45 | 321 Ball bearing | Gcr15 |

| 330 Bearing box | HT 200 | 921.1 Locknut | 304/316/316L | 525 Bearing bushing | 45 |

| 360 Bearing gland | HT 200 | 818.2 Rotor assembly | Permenant magnet/304/316/316L | 400 Sealing gasket | PTFE |

| 681 Shield | 45/Aluminium | 211 Pump shaft | 304/316/316L | 400.1 Sealing gasket | PTFE |

| 840 Coupling | HT200/45 | 421 Oil seal | Fluorubber |

Structural diagram

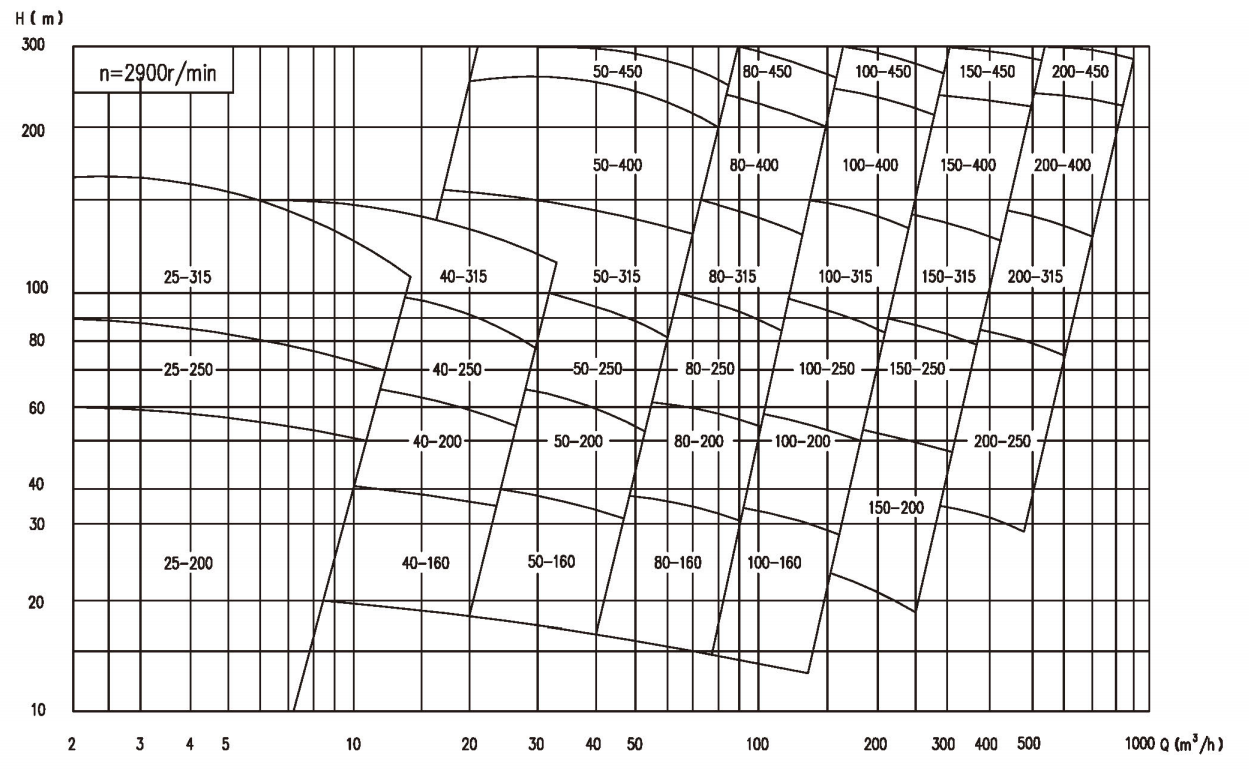

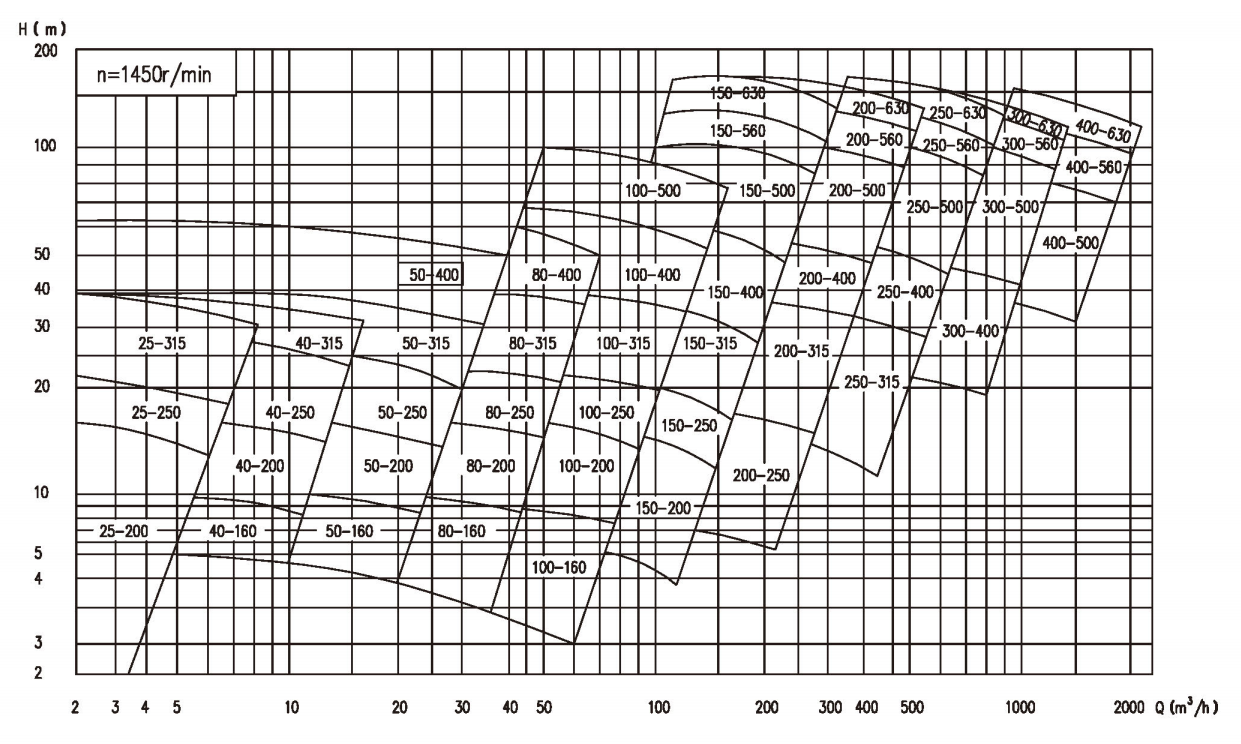

Performance range

Design pressure :2.5~5.0MPa, Flow :5.5~1900m³/h, Lift :16~250m, Power :2.2~500kw.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

It finds extensive application in the transportation processes within various fields such as polypropylene centrifugal pump for chemical industry, petrochemical, pharmaceutical, and printing and dyeing industries. It is particularly suitable for handling the transportation of liquid media that are flammable, explosive, toxic, harmful, corrosive, or valuable.

Others